The Basics of Motor Starters

You likely are familiar with motor starters if your line of work or business involves motors. However, not everyone is aware of the function of the starter in motors, despite the fact that these dependable devices are essential to safeguarding both the motor and workers in the workplace. In light of this, we’ll go through the definition of motor starters, the many types of starters, and a general overview of the starter industry today.

How a Starter Motor Works

Similar to a relay, a motor starter, motor controller, or electric motor starter is a tool used to turn on and off a motor. These tiny gadgets are surprisingly easy to use. Although they primarily serve as switches, they are essential to control any motor in an industrial context.

A motor starter is primarily a safety device. Manually starting an engine every time is not only time-consuming and tedious, but it also poses an unnecessary risk. Operators have a quick and easy alternative in motor starters to both start and stop motors remotely. The ability to safely turn down an engine may not seem important, but it is. And starters offer precisely that.

How a Starter Motor Works

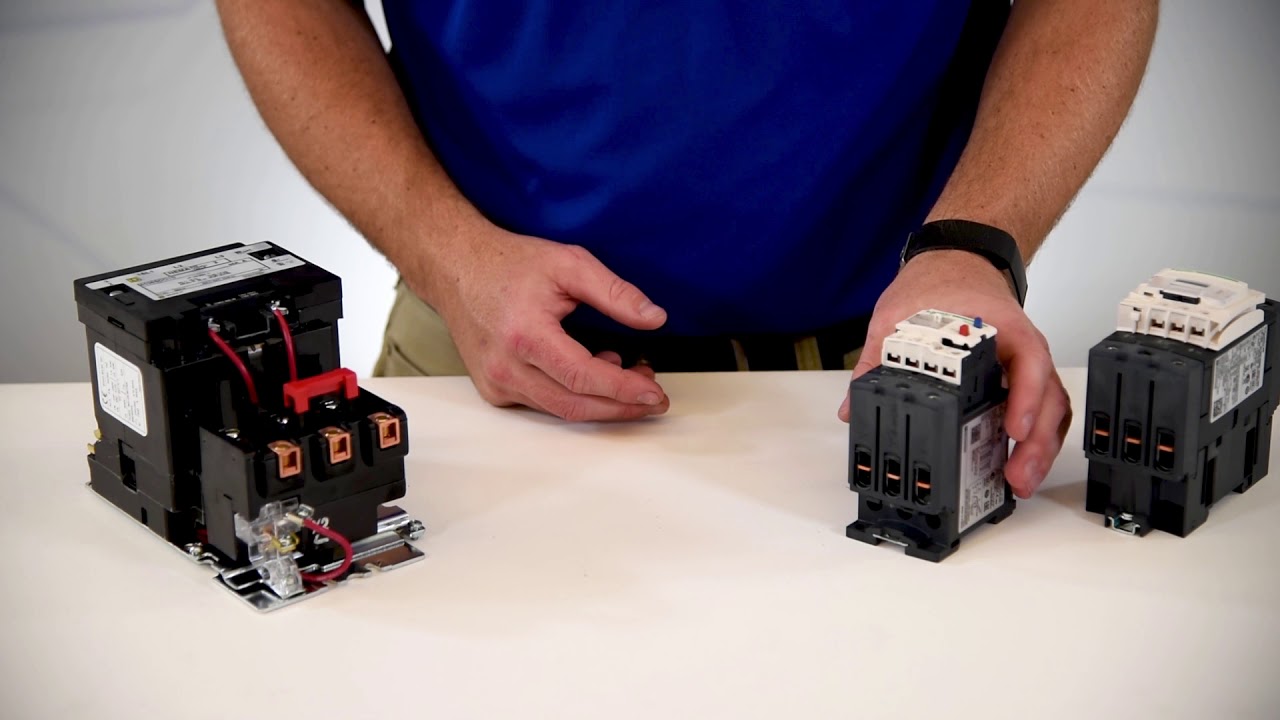

We must examine the overload protection circuit and an electrical contactor, which are present in all models, in order to understand how starters operate.

What we typically think of when we think of a switch or relay is an electrical contactor. This electromechanical device has the ability to establish or revoke a connection between two circuit points. As a result, when it is turned on, the circuit is finished, and when it is turned off, the circuit is interrupted, stopping the flow of electricity.

The motor’s integrity is safeguarded by the overload protection circuit. If an overload occurs, the OPC can recognize it and stop the energy flow, protecting the motor and any associated devices from damage.

Types of Motor Starters

Based on the operation of their electrical contactors, the various kinds of motor starters are categorized. Each starter might therefore have a unique start-up process and respond differently to electricity surges and interruptions. The many starting varieties and their distinctive characteristics are listed below.

1.Manual

The oldest product on the market is a manual motor starter. They have a simple design with an On/Off switch and a relay, making them easy to use but constrained in some ways.

These motor starters traditionally don’t offer a mechanism to cut off the remaining power in the event of an interruption. However, they can de-energize the circuit during a power outage to avoid accidental reactivation. These starters are therefore utilized when a power interruption necessitates that machinery totally shut off for reasons of safety.

2. Magnetic

The conventional manual switch is replaced with an electromagnetic mechanism in a magnetic motor starter. Closing and opening contractors are handled by a collection of electromagnets, and as a result, they can operate automatically if necessary. A magnetic starter must by default be restarted after shutting off due to a power outage. However, if a particular motor requires constant work, they can be connected to restart themselves automatically. Because of this, they are more adaptable and suitable for automation than manual starters.

3.Reversing

Instead of having only one set of contactors, a reversing motor starter has two. These double contactors’ primary function is to enable the system to rotate in either direction depending on which connection is active. These starters use mechanical and electrical interlocks to make sure that only one contactor can close at once as a safety precaution.

4.Soft

The best way to recognize a soft start motor starter is by its digital components. These starters are made with the intention of gradually boosting the motor’s charge and speed. As a result, the motor can “warm-up” rather than starting out at full power. Typically, this is done to protect the motor from harm or to keep the electrical source from becoming overworked.

Functions of Motor Starters

We can sum up each of the key categories of motor starters now that we’ve seen them. Not all starters can perform all of these tasks, but by utilizing their diverse types, any of these requirements can be easily met. Therefore, without further ado, let’s examine the primary purposes of motor starters:

Safe activation of a motor:

By reducing the process of turning on a motor to a single switch, starters make daily interactions with them safer and simpler.

Safe deactivation of a motor:

Nobody should downplay the significance of being able to remotely turn off motors since a moving motor is more hazardous than one that is not in motion. As a result, a motor’s safe deactivation might be thought of as being even more crucial for an operator.

Protect motors from current irregularities:

Every system is susceptible to sudden spikes in electricity. Any motor linked to a starter is automatically safer because all motor starters have an overload protection circuit.

Reverse the direction of a motor:

A motor can be started in either direction with the help of reversing starters. A reversing starter can make the procedure simpler even though it isn’t required for all processes.

Automatic reactivation of a motor.

In the event of a power interruption, magnetic starters can be set to reactivate automatically. This eliminates the human aspect from the equation, which is crucial for businesses where robots are supposed to operate continuously.

Conclution

A motor starter’s primary purpose is to simply give users a quick and simple way to turn on and off motors as needed. Nevertheless, depending on the beginning type, they can perform more sophisticated duties. The fact that they can control voltage, restart themselves, and reverse a motor makes them essential pieces of equipment in any industrial situation. Although motor starters appear straightforward at first glance, they are among the most dependable instruments available.