industrial motor starter manufacturer in India

In the rapidly evolving industrial landscape of 2026, choosing the right industrial motor starter manufacturer in India is no longer just about buying a switch; it is about investing in the longevity and efficiency of your heavy machinery. As India pushes toward becoming a global manufacturing hub, the demand for high-performance motor control solutions has reached an all-time high.

Whether you are managing a textile mill in Coimbatore, a chemical plant in Gujarat, or a mining operation in Odisha, your choice of an industrial motor starter manufacturer in India directly impacts your operational downtime and energy costs.

1. Why the Choice of Motor Starter Manufacturer Matters

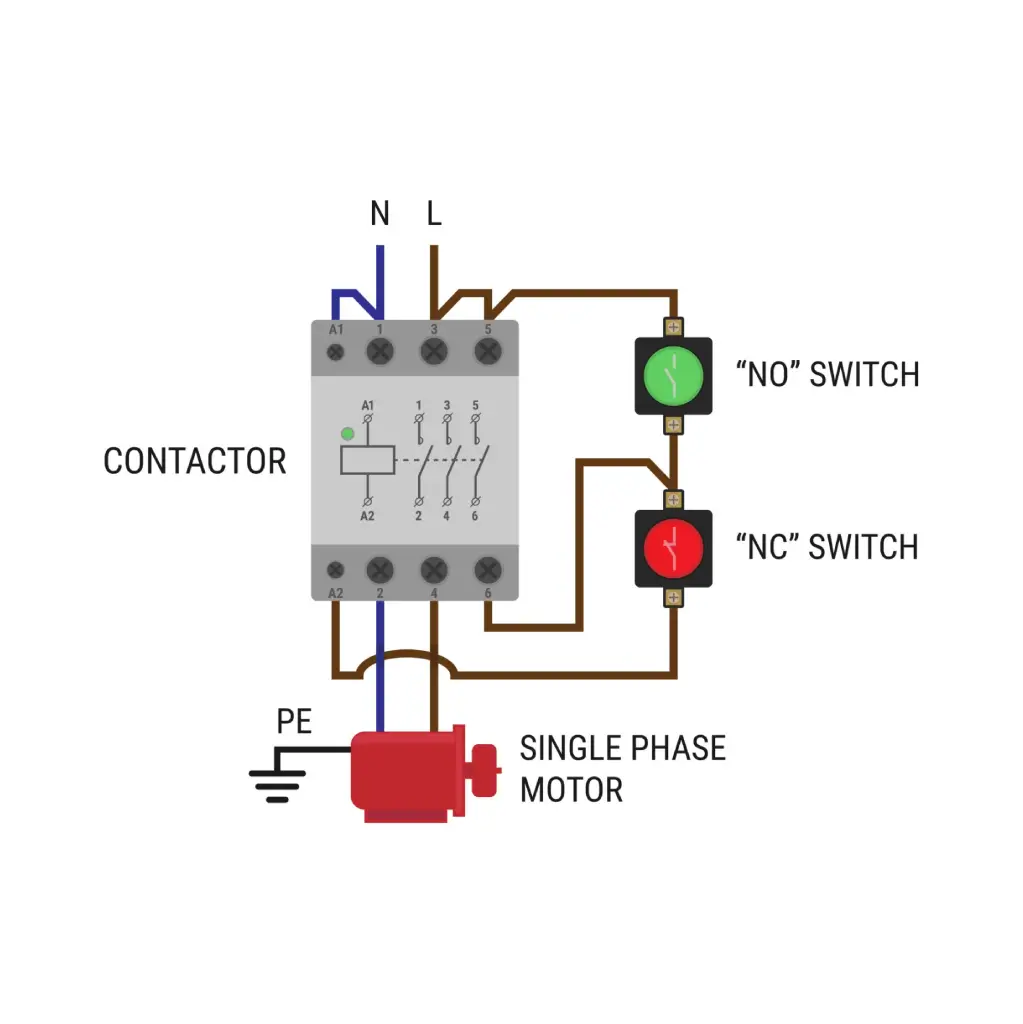

Electric motors are the workhorses of the industry. However, starting a motor directly across the line can lead to a massive inrush current—often 6 to 8 times the rated current. This surge stresses the electrical grid and causes mechanical wear on belts and gears.

A premier industrial motor starter manufacturer in India provides advanced solutions like Soft Starters and Star-Delta Starters that mitigate these risks. By choosing a manufacturer with deep expertise, you ensure that your protection relays are calibrated to handle the specific voltage fluctuations common in the Indian power grid.

2. Top Industrial Motor Starter Manufacturers in India (2026)

Based on market reliability, technical innovation, and after-sales support, here are the leaders in the Indian market today:

Larsen & Toubro (L&T) Electrical & Automation

As a titan in the Indian electrical sector, L&T remains a dominant industrial motor starter manufacturer in India. Their “MK1” and “ML” series are legendary for their ruggedness.

Best for: General-purpose industrial applications and agricultural pumps.

Key Feature: High-quality contactors that withstand millions of operations.

BCH Electric Limited

With over 60 years of experience, BCH Electric is a pioneer in low-voltage switchgear. They specialize in starters that perform in harsh environments—dusty, humid, and high-temperature settings.

Best for: Heavy-duty industries like steel and cement.

Key Feature: Custom-built motor starter panels.

ABB India

ABB brings global Swiss-Swedish technology to local manufacturing. They are the go-to industrial motor starter manufacturer in India for intelligent motor control and IoT-enabled soft starters.

Best for: Automated factories and smart manufacturing.

Key Feature: Seamless integration with PLC and SCADA systems.

Siemens India

Siemens offers the SIRIUS range of starters, known for their compact design and energy efficiency. Their authoritativeness in the field of automation makes them a preferred choice for high-precision applications.

Best for: Modern production lines requiring minimal space.

Key Feature: Modular design for easy maintenance.

3. Key Technologies Shaping the Indian Market

The year 2026 has seen a shift from manual to fully automated and “Smart” starters. When you evaluate an industrial motor starter manufacturer in India, look for these specific technologies:

A. Digital Soft Starters

Unlike traditional Star-Delta starters, soft starters provide a smooth ramp-up. They reduce mechanical shock significantly, extending motor life by up to 30%.

B. IoT and Predictive Maintenance

Modern manufacturers are now integrating Wi-Fi or GSM-based monitoring. This allows engineers to track motor health, current consumption, and fault history from a smartphone app.

C. IE4/IE5 Compatibility

With the rise of Super Premium Efficiency motors, starters must now be designed to handle the unique starting characteristics of high-efficiency permanent magnet motors.

4. How to Evaluate an Industrial Motor Starter Manufacturer in India

To ensure trustworthiness and quality, use this checklist before signing a procurement contract:

| Criteria | What to Look For |

| Certifications | ISI mark, CE certification, and compliance with IEC 60947 standards. |

| Service Network | Does the manufacturer have a service center in your city for quick repairs? |

| Customization | Can they provide specific enclosures (IP55, IP65) for your environment? |

| In-House Testing | Do they have NABL-accredited labs for testing thermal overload relays? |

5. Regional Hubs for Motor Starter Manufacturing

If you are looking for a local industrial motor starter manufacturer in India, certain cities have become specialized clusters:

Ahmedabad & Vadodara: Known for power electronics and soft starter innovation.

Pune: The hub for automotive and heavy engineering starters.

Coimbatore: Specializes in agricultural and textile motor control solutions.

Delhi/NCR: A massive market for both standard and customized starter panels.

6. The Economic Impact: Sourcing Locally

By choosing a domestic industrial motor starter manufacturer in India, businesses save significantly on import duties and logistics. Furthermore, local manufacturers understand the “Indian Condition”—where voltage can drop to 320V or spike to 480V unexpectedly. Their products are engineered with wider tolerance bands compared to strictly European-spec imports.

Cost Overview (Estimated 2026 Prices)

DOL Starters: ₹1,200 – ₹4,500

Star-Delta Starters: ₹5,000 – ₹25,000

Digital Soft Starters: ₹15,000 – ₹1,50,000+ (depending on HP)

Conclusion: Investing in Reliability

The role of an industrial motor starter manufacturer in India has evolved from being a component supplier to a strategic partner in energy management. Brands like L&T, BCH, and ABB India provide the expertise and trustworthiness required to keep the wheels of Indian industry turning without interruption.

Protecting your motors today means preventing a production halt tomorrow. Always prioritize quality over the lowest bid to ensure your facility operates at peak efficiency.

Frequently Asked Questions (FAQ)

1. Who is the leading industrial motor starter manufacturer in India for heavy-duty applications?

As of 2026, Larsen & Toubro (L&T) Electrical & Automation and BCH Electric remain the most trusted names. L&T is widely recognized for its vast expertise in rugged contactors, while BCH is an authoritative industrial motor starter manufacturer in India for harsh environments like steel mills and mines. Other global leaders with significant Indian manufacturing hubs include ABB, Siemens, and Schneider Electric.

2. What types of starters do Indian manufacturers typically offer?

A top-tier industrial motor starter manufacturer in India usually provides a comprehensive range of products, including:

Direct-On-Line (DOL) Starters: Ideal for small motors (up to 5HP).

Star-Delta Starters: The standard for medium-sized industrial motors to reduce starting current.

Digital Soft Starters: Advanced solid-state devices for smooth acceleration and energy efficiency.

Variable Frequency Drives (VFDs): For applications requiring precise speed control and maximum power savings.

3. Why should I choose an industrial motor starter manufacturer in India over imported brands?

Choosing a domestic industrial motor starter manufacturer in India offers several strategic advantages:

Grid Compatibility: Indian manufacturers design products to handle local voltage fluctuations (320V–480V).

Cost-Efficiency: You save on high import duties and international shipping.

After-Sales Support: Quick access to spare parts and on-site service engineers, ensuring minimal downtime for your plant.

4. How do I verify the trustworthiness of a motor starter manufacturer?

To ensure you are dealing with a reputable industrial motor starter manufacturer in India, verify the following:

Certifications: Check for ISI (Bureau of Indian Standards) marks and IEC 60947 compliance.

Track Record: Look for a manufacturer with at least 10–15 years of experience in the power sector.

Testing Facilities: Trusted brands have in-house, NABL-accredited labs to test thermal overload relays and short-circuit withstand capacities.

5. Can an industrial motor starter manufacturer in India provide IoT-enabled solutions?

Yes. By 2026, many leading manufacturers have integrated Industry 4.0 technologies. A modern industrial motor starter manufacturer in India now offers “Smart Starters” that feature Wi-Fi/GSM connectivity, allowing for remote monitoring, predictive maintenance alerts, and real-time energy consumption tracking through mobile apps or SCADA systems.

6. What is the average lead time for custom-built starter panels in India?

While standard DOL or Star-Delta starters are often available off-the-shelf, a specialized industrial motor starter manufacturer in India typically takes 2 to 4 weeks for custom-designed MCC (Motor Control Center) panels. This duration includes engineering design, assembly, and rigorous factory acceptance testing (FAT).