Complete Guide About Low Voltage Electric

Homeowners require internet access, illumination, and automation controls. Construction companies today are required to install low voltage electric systems. Today’s homes commonly have electrical appliances of many types. This explains why the majority of contractors and property owners have chosen low voltage electric. A distinct game is played when low voltage equipment is used. To get the most of your low voltage electrical application, it is crucial to learn more about low voltage electrical. Read on to learn everything there is to know about low voltage electric.

Classification of Voltages

Voltage, or the difference in electric potential between two places, is sometimes referred to as the electric potential difference, electric tension, or electric pressure. Electrons in a conducting loop migrate because of the voltage present. Without power, essential tasks like lighting cannot be completed. The voltage is divided into the following categories.

High Voltage

Transmission from the power plant frequently uses high, extra-high, and ultra-high voltage. This amount of power transmission boosts efficiency. High voltage transmission is accompanied with lower current, allowing for the use of smaller and lighter cables. Construction costs for electrical lines and towers can be decreased by using cables that are lighter and thinner.

Around 115 000 to 230 000 volts of alternating electricity are considered higher voltages. From 345,000 to 765, 000 volts of alternating current are considered extra-high voltages. In the US, alternating current is transported at a voltage of over 450 000 volts.

Medium Voltage

Large enterprises and factories that use a significant amount of power use medium supply voltage. Electrical variation analysis is used by these factories and big businesses to enhance operations by raising voltage and lowering amperage. Medium voltage-using businesses and factories require a backup power source. Generators that produce 13,800 volts of alternating electricity are commonly used in industries.

Low Voltage

Low voltage supply is defined as 600 volts of alternating current or less. It is frequently used in automated manufacturing. For better use, low voltage is separated into supply and control.

The Advantages of Using Low Voltage Electric

The majority of the electrical equipment in our homes and workplaces runs on low voltage, while high voltage electric is ideal for transmission lines and factories that consume excessive amounts of electricity. Low voltage direct current has so many benefits. Utilizing low voltage electrical equipment, for instance, reduces costs and improves safety. The energy efficiency of low voltage electrical supply is also increased. Low direct current electricity is provided by the majority of renewable energy sources, including solar, hydro, and wind.

Since low voltage electric systems generate less heat than high voltage electric systems, they are also growing in popularity. By minimizing the requirement for cooling, heat reduction enables energy savings.

The Application of Low Voltage Electric

Due to the advantages they provide, low voltage electric has become a standard component in most contexts. Here are a few examples of low voltage electrical applications.

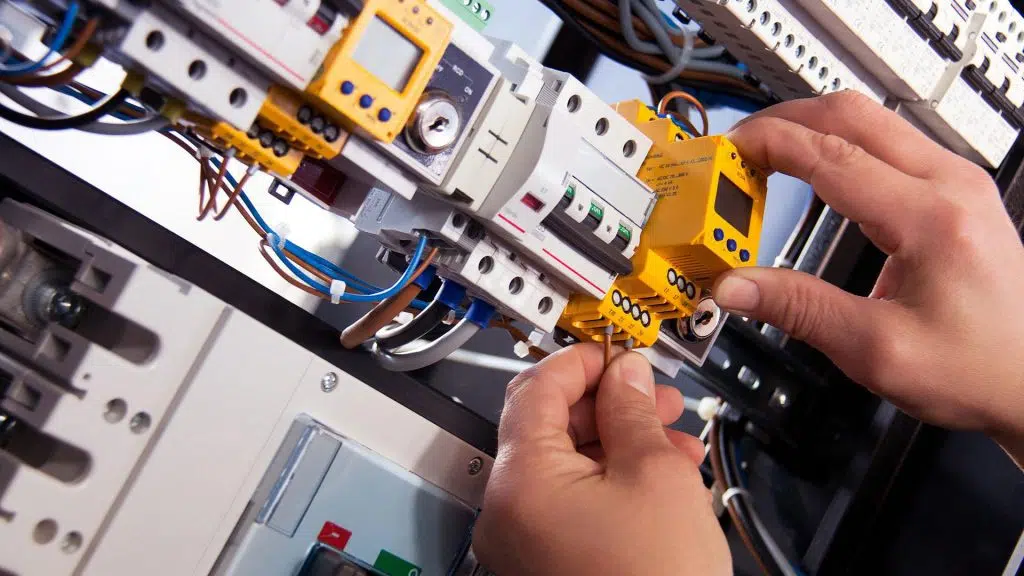

Circuit Breaker

Circuit breakers, also referred to as automated switches, are used in low voltage distribution systems to control unpredictable on-off times. In the event of a short circuit, under-voltage fault, or overload, circuit breakers can shut off the faulty circuit. They can be divided into:

Circuit breakers for frames are employed as safety measures.

circuit breakers with current limitations.

- Frame circuit breakers are used for protection.

- Current-limiting circuit breakers.

- Direct current fast circuit breakers.

- Plastic case circuit breakers, used as control switches for lighting circuits, motors, and electrical heating circuits.

Controller

Controllers are manually operated and are used to control the switchgear for high current in the main circuit. Cam controllers, plane controllers, and drum controllers are the commonly used types of controllers. They directly control the start, stop, commutation, and braking of motors in lifting equipment. Moreover, controllers also regulate the speed. Cam controller has a large contact capacity since it is mostly used than other controllers.

Contractor

Controlling the motor, welding machine, capacitor bank, and electric heating is the contractor’s responsibility. Contractors have the option of an automatic conversion between alternating and direct current. They are frequently utilized in circuits for automatic control. Direct current contractors and alternating current contractors are the two different sorts of contractors.

A contact system, electromagnetic mechanism, and arc-control devices are all features of alternating current contractors. They also include housings, contact pressure springs, response springs, buffer springs, and transmission mechanisms.

Starter

The starter is a trio of low-voltage control devices that is used to remotely start and stop a three-phase cage motor. The most popular kind of starters are electromagnetic ones. They are made up of contractors and thermal relays.

Master Switch

The control circuit receives on-off orders from the master switch, which enables the control circuit to carry out the intended function. Master switches are frequently used on buttons, proximity switches, main controllers, travel switches, footswitches, selector switches, and universal conversion switches.

Resistor

All electric equipment need resistors to regulate low voltage, high electrical current in direct current lines. They are also employed in electrical motors to control speed, start, and brake.

Capacitor

Originally known as a condenser, the capacitor is a passive two-thermal electrical component that stores energy in the form of an electrical charge. All capacitors have two electric plates separated by insulators.

How to Use Low Voltage Equipment Safely

Electric shock from low voltage current might result in harm or even death. Burns, numbness, loss of consciousness, seizures, chest discomfort, abdominal pain, and difficulty breathing are all signs of low voltage electric shock. Following are some tips for using low voltage equipment safely:

- Assess all the risks associated with your task.

- Understand the system.

- Minimize your exposure.

- Look for exposed live metal and cover it.

- Reduce energy.

- Remember to use one hand with your face and body to the side while performing the task.

Conclution

Hey there! So, let’s talk about low voltage electric systems. Basically, these are electrical systems that operate at a lower voltage level compared to your regular household outlets. They are commonly used in various applications, such as residential lighting, audiovisual setups, security systems, and telecommunications.

One of the main advantages of low voltage electric is safety. Since the voltage levels are much lower, the risk of electrical shock or fire hazards is significantly reduced. Additionally, low voltage electric systems are more energy-efficient as they consume less power compared to higher-voltage systems.

When it comes to installation and maintenance, it’s important to consult with a licensed professional who can ensure proper wiring and adherence to safety standards. There are also different types of low voltage electric cables and connectors available in the market that cater to specific needs.

Overall, understanding low voltage electric systems is essential for anyone looking to enhance their home or workplace with efficient and safe electrical solutions.